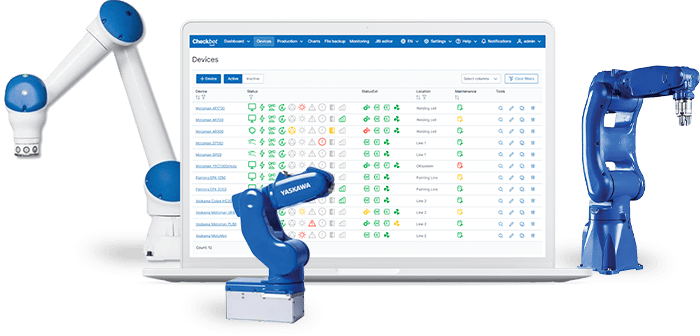

With Checkbot, you get a detailed overview of the work and status of your robots in real-time. With remote supervision, you save time and operating costs, you can solve unexpected situations in production faster. You will prevent unplanned production downtime and economic losses by monitoring current operating values and analyzing them.

Proven in real production

Fast implementation anywhere in the world

Low initial infrastructure requirements

Supported by manufacturer

Easy adoption by key users

Maintenance & support provided by a well-established company

Checkbot is a tool for efficient production monitoring. It will enable you to monitor the entire operation online from one place and, for selected models, remote access to the pendant. It saves the time of your employees, especially technicians, service workers, and programmers. It stores the selected data in a database so you can further analyze it. And for an even better overview, you can watch the work of the robots via webcams.

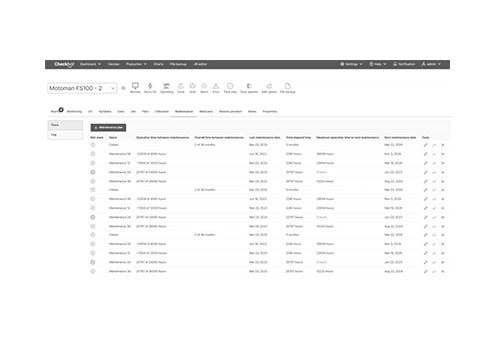

With Checkbot, you schedule service inspections at pre-given times or, based on the collected data and their analysis, the application will notify you of the need for maintenance. You will detect possible defects of the robot in advance and save the costs of unexpected repairs. You are continuously and clearly informed about the dates of planned inspections. It is possible to manage all documentation related to maintenance in the application.

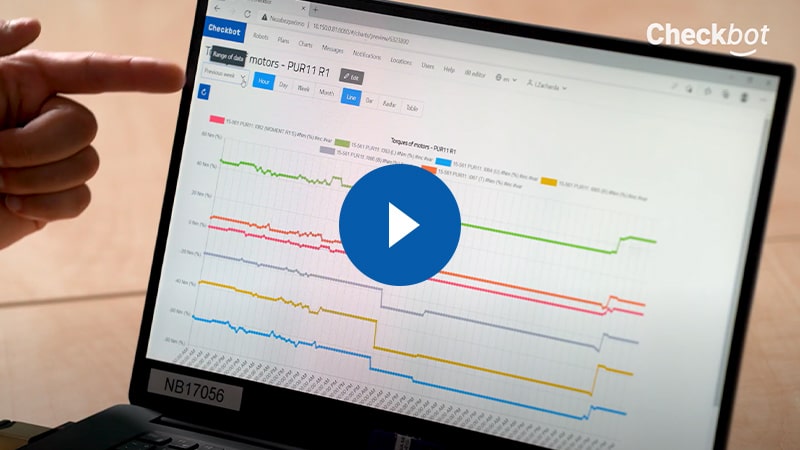

Recuperated energy monitoring, parameters of welding, energy consumption, temperature, torque, and production time. Thanks to Checkbot, you can continuously monitor and save these and other values. You will get a perfect overview of manufactured products, which you can also use as a basis for an audit or further analyses. You can immediately react to exceeding the defined conditions thanks to an e-mail notification. You can adapt the settings to your own needs at any time.

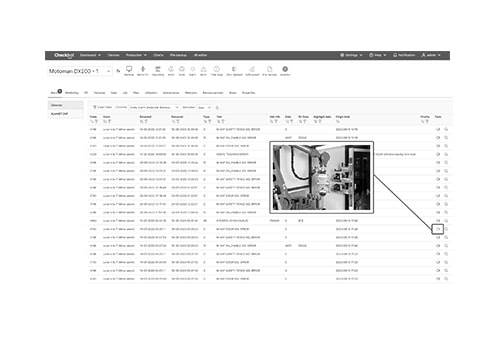

You are immediately notified by e-mail about all unexpected events. To find out the cause, there is a record of the robot's work from the camera just before the event, for its removal there are instructions with the recommended procedure. Quick reactions to critical situations in production will save you the cost of downtime of the robot or the entire production line.

Setting up backups and monitored parameters is simple and can be done on multiple devices at the same time. Regular backup of programs and device settings then takes place automatically and during full operation. This saves workers time, reduces downtime, and enables quick recovery in the event of unexpected events. The remote management of files stored on the device enables not only supervision but also file downloads and job uploads.

The application provides a complete overview of all recorded values and events, including monitoring of their occurrence. You can filter, group, and display the collected data according to selected periods in various types of graphs. You will get a long-term undistorted overview of all monitored indicators.

Monitoring of production effectiveness (Overall Equipment Effectiveness) along with monitoring of manufactured products will provide you a quick overview of the actual state of your production line, helps to uncover hidden robot reserves and, as a result, helps increase your operating profit. An overview of produced products, including the time of their production, will also serve as a basis for the audit.

Our specialists from OKsystem will help you with deployment, putting into operation, and training to use the application effectively. After that, our technical support is at your disposal. Thanks to the constant development and implementation of new trends and requirements, your application will never get old. We guarantee long-term trouble-free and safe operation.

Do you want to have total insight into the performance of robots in your production? To choose the monitored data that fit your needs and stay on top of your projects? Our application for real-time monitoring and analysis of robot work will help you with that. With it, you will make better decisions in the future.

The Doosan Bobcat EMEA manufactury in Dobris, which manufactures agricultural and construction machinery, monitors the real-time status of robots in the production line via Checkbot web application. How do they use the app in production and what do they see as its biggest benefits summarises Jaroslav Melen, Subject Matrix Expert Automation at Doosan Bobcat EMEA.

Checkbot monitors the production line based upon parameters you can specify in real time, and it alerts you immediately when there is a problem. This results in efficiency, predictability, and the ability to react quickly. The main advantages for CS Borgers are summarized by Mr. Ladislav Zacharda, Head of Robotic Technologies.

Checkbot is not only used in manufacturing, it also plays a significant role in educating future robotics experts. In 2021, we equipped one of the most modern robotics classrooms in the Czech Republic at the Secondary Technical School of Electrical Engineering in Ječná, Prague. The benefits for education are summarized by Petr Procházka, a teacher at SPŠE Ječná.

Write to us on checkbot@oksystem.cz or fill out the contact form.

We will get back to you as soon as possible.

Czechia, Slovakia

Martin Kouba

Poland

Michal Kotrouš

other markets

Martin Kisugite

OKsystem a.s., Na Pankráci 125, 140 00 Praha 4

IČ: 27373665 DIČ: CZ27373665

+420 236 072 111

info@oksystem.cz www.oksystem.cz

OKsystem entered in the Commercial Register maintained by the Municipal Court in Prague, Section B, file 20326.

Please fill in the items marked with *, they are important to us. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.